See live, component by component, selected from the manufacturing file.

See captured pictures taken in auto mode

See magnified components in manual mode, also to adjust fiducial positions

Automatically scans the circuit board and takes shots of each component using the same file used for manufacturing. It can handle even multiple circuits on the same board.

Advantages:

Cost compared to competing solutions

Time saved compared to other manual or semiautomatic solutions

Total estimated savings

Indicative data computed with an estimated average of other competing solutions, this indication cannot be used as a comprhensive assessment of the costs and savings because they may include solutions or proposals that may change over time.

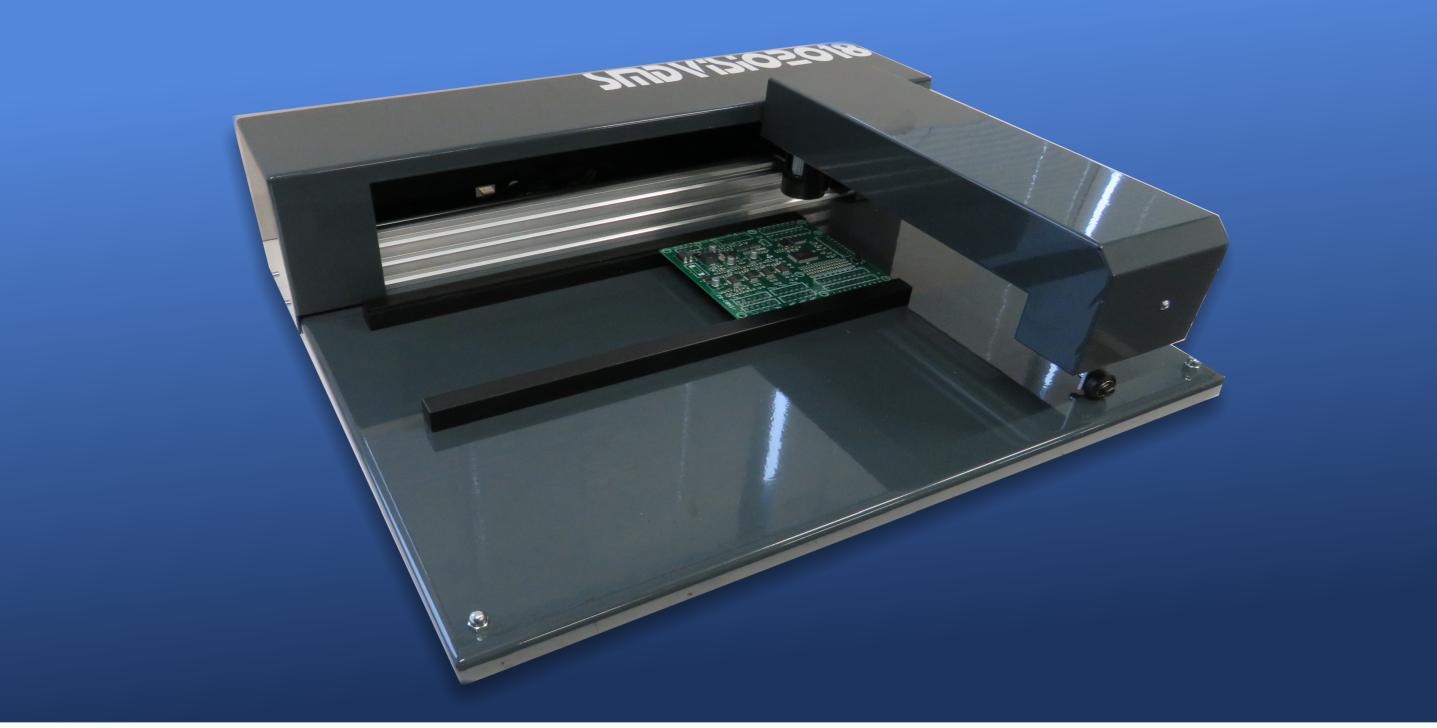

SMDVISIO is a semiautomatic system for the optical inspection of SMD and PTH components on printed

circuit boards.

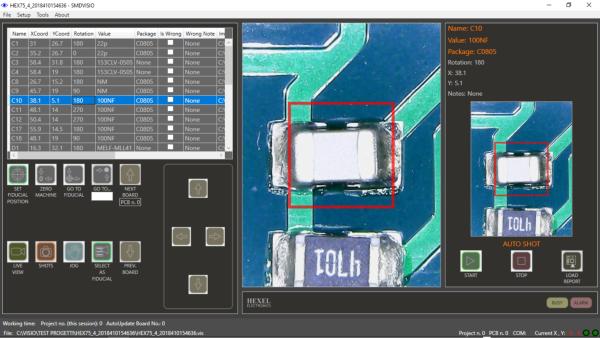

The machine allows the simplification of the operations related to the inspection of circuit boards by simultaneously

providing a magnified image of each mounted component, its data (code, value, mounting position & orientation)

and a reference picture of its correct installation on the board. By comparing these information with the actual mounted

component an operator can easily verify the correctness of the assembly.

The machine works on with any computer with Windows10 or higher, and requires two free USB 2 ports where two data-exchanging cables have to be connected in order to

let the computer talk to the machine and viceversa. The machine has its own internal controller that receives the commands sent by the user by the mean of the provided

computer software. To power the machine a 230V (or 120V for some other countries) 50/60Hz 6A source is required.

File compatibility SMDVISIO can read most of the manufacturing files commonly generated by CAM processors and used in pick-and-place machines.

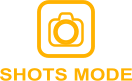

LIVE MODE In the LIVE mode the SMDVISIO positions the camera on the component selected in the data table and reproduces the image with the data of the component under consideration.

SHOTS MODE In SHOTS mode the SMDVISIO automatically acquires the images of all the components in the data table and associates them with the component database. It is possible to recall the images that are reproduced alongside the data of the component under examination.

JOG MODE In JOG mode it is possible to move the camera using the arrow keys of the keyboard or with the arrow buttons of the graphic interface in order to easily inspect the circuit board. The minimum movement is 0.1mm, while with the SHIFT key combination the minimum displacement is 2mm. With the combination of the CTRL key the minimum displacement is 6mm. (The machine has a resolution of 0.03mm)

Image storage SMDVISIO can save the images associated to the database of the components in order to build an archive of all the circuit boards inspected.

Sample image comparison: SMDVISIO can create a reference file with the sample images of the first examined card.

These photos will be proposed alongside the magnified image of the component under inspection in order to allow the the operator to quickly and easily compare the

two images.

SMDVISIO is made in Italy.

.